Free delivery on all orders over €300. Standard Delivery Charge / €10 Read more

It is good to know that different techniques can be used to obtain a waterproof fabric. In the waterproof Hocket Equishell, there is a membrane laminated onto the fabric.

Water vapor can then pass through the Equishell, while water droplets cannot enter. This is what is commonly referred to as “breathing material”.

The Equishell Equimade uses is very light weight, soft, quiet and efficient and is produced in Europe with the highest environmental standards. It can handle a water column of 10,000 mm (i.e. 10 meters). The normal standard for rugs is 3,000 mm.

Equishell is produced in Europe.

The waterproof Equishell membrane must also be able to breathe well, otherwise it will not be a pleasant experience. Despite the name, the breathing does not refer to how well air can pass through the material.

The testing is instead based on how well the sweat (in the form of water vapor) can pass from the body through the fabric and then evaporate. In order to keep your horse comfortable on the inside, both the outer fabric and the lining should have good breathability – i.e. the ability to pass through moisture. Even when it is cold, the horse will transpire. Therefore, it is important to have sufficient breathability so that condensation from the body will not be enclosed closest to the body.

The standard for horse rugs is a breathability of 3000 g/m2/24h before the first wash (the values normally decreases after washing).

Equishell used in Hocket® is tested for at least 10 000 g/m2/24h – after five washes.

The reason we have chosen Equishell membrane, is that it is more than three times more effective. The air can always circulate from the skin, without any damp feeling.

► Lighter filling used in some of the most extreme performance garments for humans is new to the equine industry.

► Light and regulated heat level – warmth when needed and temperature controlled when necessary.

► Think new superior warmth-to-weight ratios without extra weight.

► Comfortable microclimate with high air circulation.

► Soft Equifill with short dry time and high durability.

One Hocket® is enough, don´t overrug.

The technical and light Equifill insulation has been developed for extreme requirements. Used for e.g. arctic climate sleeping bags, outerwear, gloves or shoes during high-altitude expeditions.

It is good to know that it is not possible to compare the effect of filling material by comparing the weight.

That is why we use CLO-value.

The effect of the insulation is mainly determined by the:

► structure of the fibres

► composition of the fibres

► how the fibres were treated

► the construction of the product itself.

The unique Equifill solution creates a heat capability so it is possible to keep warm without carrying excessive weight. Hundreds of thousands of continuous strands of synthetic fibres are used in a unique Equifill heating solution. The heat is also maintained extremely well in the hollow fibres and provides a heat/weight ratio which is extremely good.

With Equifill a very comfortable microclimate is created with high air circulation. This ensures that the horse’s heat level can be regulated, so that it gets warmth when needed and temperature controlled when necessary.

You know your horse the best, we also know that people tend to overrug the horse.

Individual parameters to consider is:

► Temperature – the temperature outside

► Age and breed of the horse and whether it is an individual that is naturally warm or cold

► How much and how often the horse is clipped

► Rain/Humidity

► Wind

► Activity level, i.e. whether the horse is stationary or in motion and/or eating

► Heat release = sweating or evaporation

► Time spent outside on inside

We are confident this is a new level of insulation and construction. This helps cover the exposed parts of the body and prevents the horse from getting cold without being exposed to unnecessary weight or clammy feeling.

Ensure less weight and more effective with the new innovative Hocket.

The Hocket® Cordura® fabric is treated with optimized water and dirt repellent surface that is free of PFOA (perfluorooctanoic acid) and PFOS (perfluorooctanesulphonic acid).

The durable water repellent surface (DWR) coating is part of the Hockets® waterproofing layer. Unlike most fabric treatments, the DWR finish has minimal impact on permeability, which means the fabric can continue to transport away moisture while the protective coating repels water and dirt.

The finish is produced in Europe with Reach, bluesign® and OEKO-TEX®.

Since abrasion impacts the effect of DWR, re-treatment should be used when water droplets no longer bead on the fabrics.

The seams on the Outdoor Hockets® are completely sealed, just like on premium ski wear. A seam with needle holes can be fine, but without a quality sealing tape the garment will lose the waterproof and protective properties of the fabric and the garment will leak. The sealing tape we use provides a quality, long-lasting seal and is widely used for outdoor garments for skiing, hiking, climbing and marine applications.

The tape is manufactured in Europe and bluesign® approved.

In addition, it is applied with the right pressure and in the right way by skilled craftsmen in a sustainable way.

The four-dimensional spacer material used in Hocket® Front is based on a unique and innovative technology.

This high performance, multifunctional distance textile has a built-in air flow, is moisture transporting and automatically recovers after compression. Its characteristics also offer:

►Comfort

►Pressure reduction

►Reduced friction and abrasion

►High breathability

►Good recovery after long stretches

►Superior cushioning

This high quality 4D spacer is often used as an ideal solution for products with orthopedic purposes, thats good to know. We like it and have also added a soft surface to fit sensitive sporthorses.

Produced in Europe.

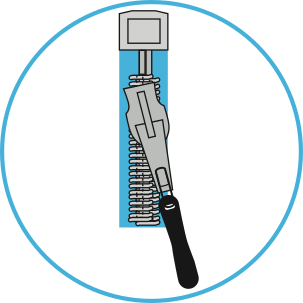

Spiral zippers connects the Hocket® Front with Hocket® Body, as well as the optional Hocket® Neck connect and closes with zippers.The zipper are the strongest construction on the market.

All parts are customizable, so it is easy to change to a correct size for Hocket® Body, Hocket® Front and Hocket® Neck parts. They are produced in Europe with high standards and meet the requirement of good ecological standards within OEKO-TEX®.

Thanks to these easy-to-handle zippers:

►Horses have a secure closing system without hard buckles under the neck

► Humans have an ergonomic easy handling product

The Equimade Hocket® uses buckles made of nylon 6/6, a thermoplastic polyamide resin.

Why use this type of buckles?

► Minimal to no risk that the horse gets hurt while at the same time offering a very user-friendly and strong solution

► Minimize the weight as much as possible

► Possibility of opening it with just one hand – even wearing gloves or long nails

► Possible to wash it in the washing machine, without having worry about either the buckles nor the washing machine

► These are often used in harsh conditions (e.g. machinery and military) and work well down to -40 °C

A high denier does not indicate that the material is strong, only that it is thicker and therefore heavier.

The crucial things that you need to know are:

► The type of fibers used

► How the thread is spun

► How the fabric is produced.

Horses should have the opportunity to use light and flexible products,

just like human athletes.

Equimade uses durable, strong and advanced Cordura® blended outer fabric without extra clumsy weight.

The outside-fabric in outdoor Hocke t® is blended with Cordura and another strong fibre to give it even more delicate features.

► Strong – Excellent resistance to tearing.

► Optimal strength-to-weight ratio.

► Good abrasion resistance.

► Dense – tight woven fabric profile.

► Woven – minimum basket weave.

The heavy-duty performance CORDURA® are made with high tenacity nylon 6,6 filament yarns and offer enhanced tear and abrasion resistance, often used for military body armour and motorcycle gear.